-

Contact

-

Call

-

Address

GHB Fall Protection Anchor Re-Certification

When it comes to fall protection testing and certification, GHB Fall Protection has the experience and expertise to perform OSHA and ANSI-mandated certification to keep your fall protection system compliant. Federal Code states that davit systems and other fall protection anchorage systems be certified by a qualified person per OSHA and ANSI safety requirements. GHB Fall Protection follows all industry safety standards, properly performing and documenting all inspections to assure current and future users that fall protection equipment is in compliance with applicable safety standards.

The licensed professionals at GHB Fall Protection are extremely knowledgeable of the guidelines, procedures and documentation required for the re-certification of various fall protection systems. According to ANSI standards, window washing suspended maintenance fall protection systems are to be re-certified before use for re-roofing or renovating, or at least every 10 years (ANSI I-14.1 Section 9.1.9). For rooftop anchor points and other active fall protection systems, the ANSI Z359 Fall Protection Code requires re-certification at intervals not exceeding five years (Section 4.6.5). Re-certification provides documented assurance by a qualified engineer that the system provides adequate fall protection for current work procedures as required by the latest standards and regulations.

Open 7 Days a Week

Contact Us

CORPORATE HEADQUARTERS

235 SW 41st St

Renton WA 98057

Fax: 425-284-2825

Email: office@ghbfallprotection.com

844.438.4429

We accept: Checks, Credit Cards, PayPal

Certification of Fall Protection Systems and Equipment

Certification of Fall Protection Systems and Equipment

After completing installation of any fall arrest system or fall protection equipment, all components are inspected and certified. Certification documents that your fall protection system and all related personal protection equipment (PPE) meets OSHA regulations. Proper signage verifies the system’s tested capabilities and operational limits and informs outside inspectors that the system has been tested by an OSHA-defined “Qualified Person.” GHB Fall Protection also provides you with a complete systems installation manual and binder.

Due to the highly technical nature of a fall protection system, OSHA requires that at minimum, an annual inspection must be performed by a qualified individual and 10 year re-certification. For 25 years, GHB Fall Protection has provided customers with a complete, turnkey solution for fall protection services including certifying the safety of systems and their components. If during a periodic safety equipment certification, any component of your fall arrest or fall protection system is determined to be damaged, we are trained to perform the necessary repairs. GHB Fall Protection personnel can also provide system training to keep your employees aware of proper use and industry best practices. The combination of these services helps to keep your employees safe and provides your company the up-to-date training and inspection documentation required by OSHA and recommended by ANSI I-14 Standard.

OSHA Regulations Regarding Re-certification

All parts of the equipment including control systems shall be inspected, and, where necessary, tested by a competent person at intervals specified by the manufacturer/supplier, but not to exceed 12 months, to determine that they are in safe operating condition. Parts subject to wear, such as wire ropes, bearings, gears, and governors shall be inspected and/or tested to determine that they have not worn to such an extent as to affect the safe operation of the installation.

Before any rope descent system is used, the building owner must inform the employer, in writing that the building owner has identified, tested, certified, and maintained each anchorage so it is capable of supporting at least 5,000 pounds (2,268 kg), in any direction, for each employee attached. The information must be based on an annual inspection by a qualified person and certification of each anchorage by a qualified person, as necessary, and at least every 10 years.

The building owner shall keep a certification record of each inspection and test. 1910.27(b)(1)(ii)

The employer must ensure that no employee uses any anchorage before the employer has obtained written information from the building owner that each anchorage meets the requirements of paragraph (b)(1)(i) of this section. The employer must keep the information for the duration of the job.

Building owner’s Responsibility – Separate from the annual inspections, building owners shall ensure equipment or anchors be re-certified 1. At periods not to exceed 10 years, 2. When equipment shows excessive wear or damage, 3. When re-roofing or renovation 4. When equipment is modified or removed from the structure

ANSI Regulations Regarding Re-certification of Fall Protection Devices

Active fall protection systems shall be thoroughly reviewed by an engineer at a frequency to be determined by the original design or similarly qualified engineer not to exceed five years. Z359.6-2009 4.6.5

ROOF ANCHOR & STRUCTURAL ANALYSIS:

- Deformations and Abnormalities: Structural Deformations can occur through applied force or changes in weather or temperature. This is often seen in davits and fall protection anchors after years of use.

- Internal and External Forces: Internal forces on materials of a structure can determine if there will be the strength to withstand over time and through external influences such as weather and other structural consequence.

- Stresses: The stresses placed on a structure such as wind in tall buildings or water on bridges piers can weaken the overall structure over time. We can determine what stresses will be imposed on a structure and how to proactively maintain it throughout its lifetime.

- Support Reactions: Understanding support reactions for permanent or temporary facade access equipment is vital in the design of these systems.

- Stability: We evaluate overall structural stability of the entire system as opposed to looking at only the temporary or permanent elements.

Proper structural analysis can save you time, money and help you to avoid dangerous situations on the job site.

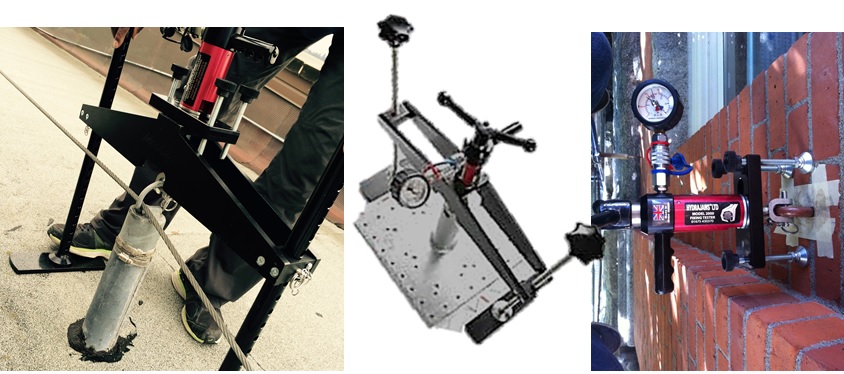

Load Testing, Certification & Inspections

Frequently Asked Questions

GHB Fall Protection Inc. can perform an on-site review of your fall protection and suspended maintenance equipment to determine if your current equipment complies with safety standards. Factors such as anchor spacing, and edge distance is examined for compliance. Existing equipment must be load tested to verify that such equipment can be certified. Our rooftop review will be supported by a written report with recommendations for any modifications. Contact us for details.

The building owner.

OSHA 29 CFR 1910.27 – Before any rope descent system is used, the building owner must inform the employer, in writing that the building owner has identified, tested, certified, and maintained each anchorage so it is capable of supporting at least 5,000 pounds (268 kg), in any direction, for each employee attached. The information must be based on an annual inspection by a qualified person and certification of each anchorage by a qualified person, as necessary, and at least every 10 years.

Each anchor must be certified by a qualified person, as necessary, and at least every 10 years. OSHA 29 CFR 1910.27 (b)(1)(ii)

However, GHB Fall Protection Inc. follows the recommendation of the ANSI A359 Fall Protection Safety Standard, Specifications and Design Requirements for Active Protection System, Paragraph 3.3.1 as follows:

“A Statement shall be made stipulating how frequently the system shall be inspected and re-certified. Periods between recertification shall not exceed 5 years.”

Therefore, all GHB Fall Protection Inc., Inc equipment dedicated to a specific building shall be re-certified by load testing under supervision of a registered Professional Engineer at periods not to exceed 5 years and shall be inspected by a Qualified Person(s) annually and before use.

NOTE: Government agencies such as OSHA use Industry Consensus Standards, such as ANSI A359 as a basis to cite safety violations.

Each anchor must be inspected a qualified person, as necessary, and at least annually. OSHA 29 CFR 1910.27 (b)(1)(ii)

Employers must not allow employees to perform suspended work unless the employer has determined that there are certified anchors capable of supporting at least 5,000 pounds.

OSHA 29 CFR 1910.27 – The employer must ensure that no employee uses any anchorage before the employer has obtained written information from the building owner that each anchorage meets the requirements of paragraph (b)(1)(i) of this section. The employer must keep the information for the duration of the job.

OSHA has provided citation enforcement guidance to regional administrators to examine both employers and buildings owner’s compliance with OSHA’s general industry fall protection systems regulation.

See letter: https://www.osha.gov/laws-regs/standardinterpretations/2017-11-20

Rope descent systems and other suspended access systems can be certified to the OSHA 1910.27 Rope Descent Systems Window Cleaning Safety Standard.

Some examples of other standards and applicable regulations include:

- • OSHA Regulations (Standards-29 CFR) 1910.27 Rope Descent Systems

- • OSHA Regulations (Standards-29 CFR) 1910.28 Safety Requirements for Scaffolding.

- • OSHA Regulations (Standards-29 CFR) 1910.66 Powered Platforms for Building Maintenance.

- • IWCA I-14.1 Window Cleaning Safety Standard

- • ANSI/ASME A120.1 Safety Requirements for Powered Platforms for Building Maintenance

Note: Some states and municipalities (e.g. State of California and New York, City of Chicago) have additional requirements that apply to window cleaning equipment.

Anchors and Rigging Sleeves:

• 1,250 lbs. Allowable load (Typical. Must be based on hoist capacity in suspended scaffold applications)

• 2,500 lbs. Test load

• 5,000 lbs. Ultimate load

Davits for Swing Stage Applications:

• 1,000 lbs. Allowable load (Typical. Must be based on hoist capacity in suspended scaffold applications)

• 2,000 lbs. Test load

• 4,000 lbs. Ultimate load

Davits for Rope Descent System Applications:

• 1,250 lbs. Allowable load (Typical. Must be based on hoist capacity in suspended scaffold applications)

• 2,500 lbs. Test load

• 5,000 lbs. Ultimate load

Monorails for Swing Stage and Rope Descent System Applications:

• 1,250 lbs. Allowable load

• 2,500 lbs. Test load

• 5,000 lbs. Ultimate load